Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

How do chemical pumps ensure safe handling of corrosive or hazardous fluids?

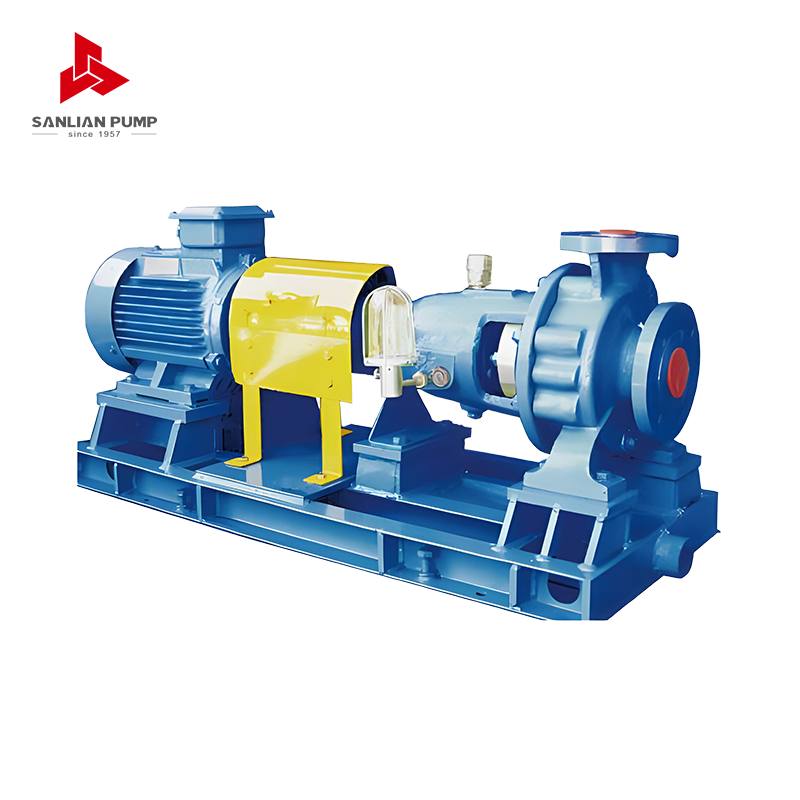

Chemical pumps play a crucial role in industries where fluids are not only valuable but also potentially dangerous. From concentrated acids to volatile solvents, the fluids they handle can corrode metals, release toxic vapors, or react violently when exposed to air. To manage such risks, the entire design philosophy of a chemical pump revolves around containment, compatibility, and control—three aspects that ensure safe handling of corrosive or hazardous liquids.

The first line of defense comes from material selection. The parts in contact with the fluid—casings, impellers, seals—are usually made from materials that do not react chemically with the liquid. Stainless steel is often used for mildly corrosive media, while for aggressive acids or alkalis, plastics such as polypropylene (PP), polyvinylidene fluoride (PVDF), or polytetrafluoroethylene (PTFE) are preferred. These nonmetallic materials form a chemical barrier that resists attack even under continuous exposure, extending the pump’s service life and maintaining purity in sensitive processes.

Another important factor is leak prevention. A small leak that would be inconsequential in a water system can be catastrophic in a chemical plant. For this reason, many chemical pumps adopt seal-less or magnetic drive designs, where the impeller is rotated by a magnetic field rather than a physical shaft connection. With no dynamic seals to wear out, the risk of fluid escaping is almost eliminated. In situations where mechanical seals are still used, manufacturers often employ double seals with a buffer fluid or gas between them—if the inner seal fails, the outer one still contains the leakage.

System control is equally essential. Pumps that handle hazardous media are typically integrated with sensors that monitor pressure, flow rate, and temperature. These sensors help operators detect anomalies such as dry running, overpressure, or cavitation before they cause mechanical failure or leakage. Some advanced systems are connected to automated shutdown protocols—if abnormal readings appear, the system immediately stops the pump and isolates the flow to prevent escalation.

For chemicals that are not only corrosive but also flammable or volatile, additional precautions are built into the pump design. Motors can be explosion-proof, and the pump housing may be grounded to avoid static discharge. Even the smallest spark could ignite vapors, so minimizing static buildup and maintaining proper ventilation are as important as the pump’s mechanical integrity.

Finally, the installation and maintenance process itself is designed to reduce exposure. Many chemical pumps are built with back-pull-out designs, allowing internal components to be serviced without disconnecting the suction and discharge lines. Some are installed within secondary containment systems—essentially protective shells—that can capture any accidental leakage before it reaches the environment or workers.

In short, chemical pumps do not achieve safety through a single feature but through the combination of resistant materials, tight sealing, intelligent monitoring, and thoughtful engineering. Their purpose is not just to move liquid from one tank to another, but to do so without letting that liquid interact with anything except the intended process path. The result is a piece of equipment that serves as both a mechanical device and a containment system—one that quietly upholds the safety and stability of chemical operations across industries.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号