Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

How Mixed Flow Pumps Compare to Axial and Centrifugal Pumps in Demanding Industrial Settings

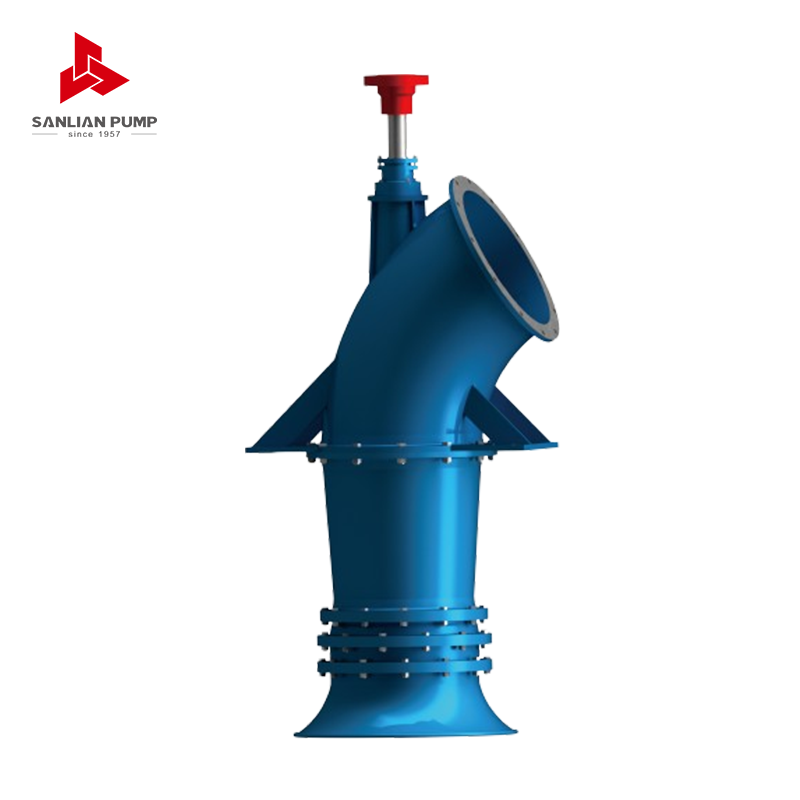

When it comes to selecting the right pump for a high-demand industrial environment, understanding the performance characteristics of different types—namely mixed flow pumps, axial flow pumps, and centrifugal pumps—is crucial. Each has its own operating principles and efficiency zones, and matching the right pump to the right application can make a significant difference in energy consumption, maintenance schedules, and overall system stability. A mixed flow pump occupies a unique niche by combining aspects of both axial and centrifugal pumping actions, which directly impacts flow rate, head, and versatility across industries.

A centrifugal pump operates by imparting velocity to the fluid via a spinning impeller and converting that velocity into pressure energy. These are ideal for high-pressure, low-flow applications and are widely used in boiler feed systems and deep-well applications. On the other hand, axial flow pumps push fluid in a straight line parallel to the shaft, offering high flow at low head—perfect for flood control, water circulation, and some marine uses. The mixed flow pump sits comfortably between these two extremes, making it a go-to choice when a balanced performance of moderate head and high flow is required, such as in municipal water supply, cooling water circulation, or agricultural irrigation.

From a performance curve perspective, mixed flow pumps exhibit a relatively flat efficiency curve across a wide operating range, which allows for stable operation under variable load conditions. This is especially useful in processes where flow demand fluctuates. In contrast, centrifugal pumps have steeper curves, meaning they are sensitive to changes in flow and head, which can result in cavitation or overloading if operated outside their best efficiency point. Axial pumps, while efficient at moving large volumes, often lack the adaptability and can become inefficient quickly when system conditions vary.

The physical construction of a mixed flow pump also gives it a practical edge. The pull-out design commonly featured in many models allows for easier maintenance and quicker part replacement without the need to disturb the main piping system. This not only reduces downtime but also simplifies operations for facilities where continuous service is critical. For customers running 24/7 systems, such convenience translates into lower lifecycle costs and more predictable servicing, which makes the mixed flow pump an asset in tightly managed operational environments.

In terms of installation footprint and space considerations, mixed flow pumps usually require a middle ground in terms of spatial allocation—larger than centrifugal pumps, but significantly more compact than some axial configurations. This makes them suitable for retrofit projects or for facilities facing space constraints but needing improved hydraulic performance. Their moderate rotational speeds also mean they often generate less vibration and noise, contributing to a safer and more compliant workplace.

From an engineering standpoint, one of the most compelling advantages of a mixed flow pump is its ability to handle liquids with low to moderate levels of contamination, all while maintaining efficient flow characteristics. This capability is particularly valuable in water treatment and industrial reuse systems where fluid cleanliness cannot always be guaranteed but where high-volume movement is still necessary. It’s precisely this balance of robustness and efficiency that makes mixed flow pumps such a reliable solution across diverse sectors.

For buyers seeking a dependable and adaptable solution backed by proven design, the mixed flow pump offers a compelling mix of performance, durability, and ease of maintenance. With years of real-world application behind our designs, we help businesses move forward—literally—with equipment they can count on, day after day.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号