Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

Understanding Chemical Pumps: A Detailed Overview

Chemical pumps are essential components in modern industrial processes, responsible for transferring a wide variety of liquids safely and efficiently. They are particularly important when handling corrosive, viscous, or hazardous chemicals, which cannot be moved using standard pumps without risking leaks, contamination, or equipment damage. These pumps find applications in numerous industries, including chemical manufacturing, pharmaceuticals, petrochemicals, water and wastewater treatment, food processing, agriculture, and energy production. Understanding the types, working principles, material selection, applications, and maintenance of chemical pumps is vital for engineers, operators, and industrial professionals aiming to maximize efficiency, reliability, and safety in their operations.

1. Introduction

Chemical pumps are specialized devices designed to transfer chemical fluids from one location to another while maintaining the integrity of both the fluid and the pump itself. Unlike general-purpose pumps, chemical pumps must be engineered to withstand aggressive chemicals, high temperatures, variable pressures, and other challenging conditions often encountered in industrial environments.

2. Classification of Chemical Pumps

Chemical pumps can be classified based on their mechanism of operation, the type of fluid they handle, and specific industry requirements. Broadly, chemical pumps fall into the following categories:

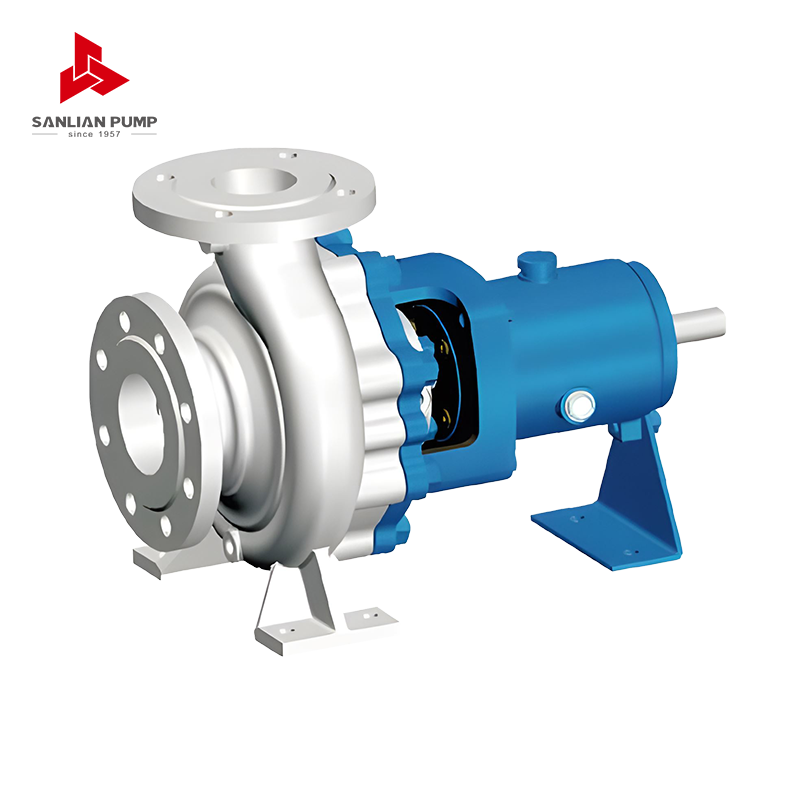

2.1 Centrifugal Chemical Pumps

Centrifugal pumps are among the most commonly used chemical pumps. They work by converting mechanical energy from a rotating impeller into kinetic energy, which is then transformed into pressure energy to move the chemical fluid through the system.

-

Advantages:

- High flow rate capability

- Smooth and continuous operation

- Simple construction with relatively low maintenance

-

Typical Applications: Water treatment chemicals, solvents, acids, and alkalis in moderate flow and pressure conditions

Centrifugal pumps can further be designed as single-stage or multi-stage pumps, depending on the required pressure and flow characteristics. Multi-stage centrifugal pumps are especially useful in applications requiring high-pressure delivery, such as boiler feedwater systems or chemical reactors.

2.2 Positive Displacement Pumps

Positive displacement pumps operate by trapping a fixed volume of fluid and mechanically forcing it through the discharge outlet. These pumps are ideal for applications requiring precise flow rates or handling highly viscous, shear-sensitive, or abrasive chemicals.

-

Subtypes: Gear pumps, diaphragm pumps, piston pumps, peristaltic pumps

-

Advantages:

- Accurate and consistent flow delivery regardless of pressure

- Capable of handling high-viscosity liquids and slurries

- Suitable for metering and dosing applications

-

Typical Applications: Polymer solutions, adhesives, slurries, and chemical dosing in precise quantities

Positive displacement pumps are widely used in industries where maintaining fluid integrity is critical, such as pharmaceuticals, where the solution may be sensitive to shear forces, or in the food and beverage sector for handling thick syrups and pastes.

2.3 Magnetic Drive Pumps

Magnetic drive pumps utilize a magnetic coupling to transmit torque from the motor to the pump impeller without the need for a direct mechanical seal. This design significantly reduces the risk of leakage and chemical exposure.

-

Advantages:

- Leak-free operation even with highly corrosive or toxic fluids

- Reduced maintenance due to the absence of mechanical seals

- High reliability in critical applications

-

Typical Applications: Acids, solvents, and environmentally sensitive chemicals in chemical processing, laboratory, or pharmaceutical settings

Magnetic drive pumps are especially valuable in applications requiring containment of highly hazardous fluids, as even small leaks can pose serious safety or environmental hazards.

2.4 Self-Priming Chemical Pumps

Self-priming pumps are designed to remove air from the suction line automatically, allowing the pump to begin transferring fluid without requiring a flooded suction.

-

Advantages:

- Simplified start-up procedure

- Can handle air-fluid mixtures without losing prime

- Ideal for applications with intermittent pumping or where suction conditions vary

-

Typical Applications: Chemical storage tanks, drainage systems, and transfer operations where the liquid level fluctuates

These pumps are particularly useful in situations where manual priming is impractical or where suction lines may occasionally run dry.

3. Materials of Construction

The chemical resistance of pump materials is one of the most critical factors in pump design and selection. Material selection depends on fluid characteristics, temperature, pressure, and mechanical stresses. Common materials include:

- Stainless Steel: Corrosion-resistant, widely used in chemical, pharmaceutical, and food industries

- Hastelloy: Exceptional resistance to oxidizing and reducing chemicals, suitable for aggressive chemical environments

- Fluoroplastics (e.g., PVDF, PTFE): Highly inert and resistant to strong acids and bases

- Bronze and Nickel Alloys: Selected for specialized applications requiring both mechanical strength and chemical resistance

Proper material selection ensures long-term pump performance, reduces downtime, and prevents contamination or hazardous leaks in sensitive industrial processes.

4. Working Principles

Different chemical pumps operate according to different principles:

- Centrifugal Pumps: Impellers spin at high speeds, imparting kinetic energy to the fluid, which is converted into pressure energy as the fluid exits the pump casing

- Positive Displacement Pumps: The pump mechanically traps a fixed amount of fluid and forces it through the discharge, ensuring precise flow regardless of system pressure

- Magnetic Drive Pumps: Torque is transmitted magnetically through a sealed coupling, rotating the impeller without a direct shaft seal

- Self-Priming Pumps: Air is evacuated from the suction chamber during start-up, creating a vacuum that draws liquid into the pump automatically

Understanding the working principle is crucial for proper pump selection, maintenance, and troubleshooting.

5. Applications in Industry

Chemical pumps are indispensable in numerous sectors:

- Chemical Manufacturing: Transfer of acids, alkalis, solvents, and reagents in controlled quantities

- Pharmaceutical Industry: Handling sterile or sensitive fluids without contamination

- Water and Wastewater Treatment: Dosing chemicals for purification, pH adjustment, and disinfection

- Petrochemical Industry: Pumping hydrocarbons, lubricants, and process chemicals under high pressure

- Food and Beverage Processing: Safe transfer of syrups, flavorings, and additives

- Agriculture: Delivery of fertilizers, pesticides, and irrigation chemicals

- Energy Production: Fuel transfer, cooling fluids, and chemical injection for power plants

The versatility of chemical pumps allows them to adapt to varying operational conditions, fluid types, and environmental requirements.

6. Maintenance and Safety Considerations

Maintenance is critical to ensure long-term performance and prevent downtime. Key practices include:

- Regular Inspections: Check seals, bearings, impellers, and casings for wear or corrosion

- Material Compatibility: Verify that pump materials are compatible with the chemicals being handled

- Lubrication and Seal Maintenance: Ensure proper lubrication of moving parts and replace worn seals proactively

- Operational Safety: Implement proper containment, follow standard operating procedures, and use personal protective equipment (PPE)

Safety protocols are essential because many industrial chemicals are toxic, corrosive, or flammable, and pump failure can lead to environmental hazards, health risks, or operational disruptions.

7. Criteria for Selecting Chemical Pumps

Selecting the right pump involves careful consideration of several factors:

- Fluid Characteristics: Viscosity, corrosiveness, temperature, and abrasiveness

- Flow Rate and Pressure Requirements: Ensuring the pump meets process specifications

- Pump Type Compatibility: Determining whether centrifugal, positive displacement, magnetic drive, or self-priming pumps are suitable

- Material Selection: Ensuring chemical resistance and mechanical durability

- Installation and Maintenance: Considering space constraints, ease of service, and long-term reliability

A well-selected chemical pump reduces energy consumption, prevents equipment failure, and improves overall process efficiency.

8. Advances in Chemical Pump Technology

Modern chemical pumps incorporate innovations such as:

- High-Performance Seals: Reducing leakage and maintenance requirements

- Energy-Efficient Designs: Optimizing impeller geometry to lower energy consumption

- Automation and Monitoring: Integration with sensors and control systems for real-time monitoring and predictive maintenance

- Advanced Materials: Use of composite materials and fluoroplastics for extreme chemical resistance

These innovations improve reliability, safety, and operational efficiency across various industries.

9. Conclusion

Chemical pumps are vital components in modern industrial systems, enabling the safe, efficient, and precise transfer of a wide range of chemicals. Understanding the different pump types, working principles, materials of construction, applications, maintenance, and selection criteria allows industrial professionals to optimize their operations, reduce downtime, and enhance safety.

As industrial processes become more complex, the demand for advanced chemical pumps continues to grow. With the development of magnetic drive pumps, self-priming systems, and energy-efficient designs, chemical pumps remain at the forefront of industrial innovation, ensuring reliable and sustainable fluid handling solutions across diverse sectors.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号