Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

Why Choose Split-Case Pumps? Understanding Their Benefits and Applications

Split-case pumps have long been a reliable workhorse in fluid transfer systems across many industries. Known for their high efficiency, easy maintenance, and robust design, they are particularly well-suited to demanding applications such as water supply, HVAC systems, industrial cooling, irrigation, and firefighting.

What Is a Split-Case Pump?

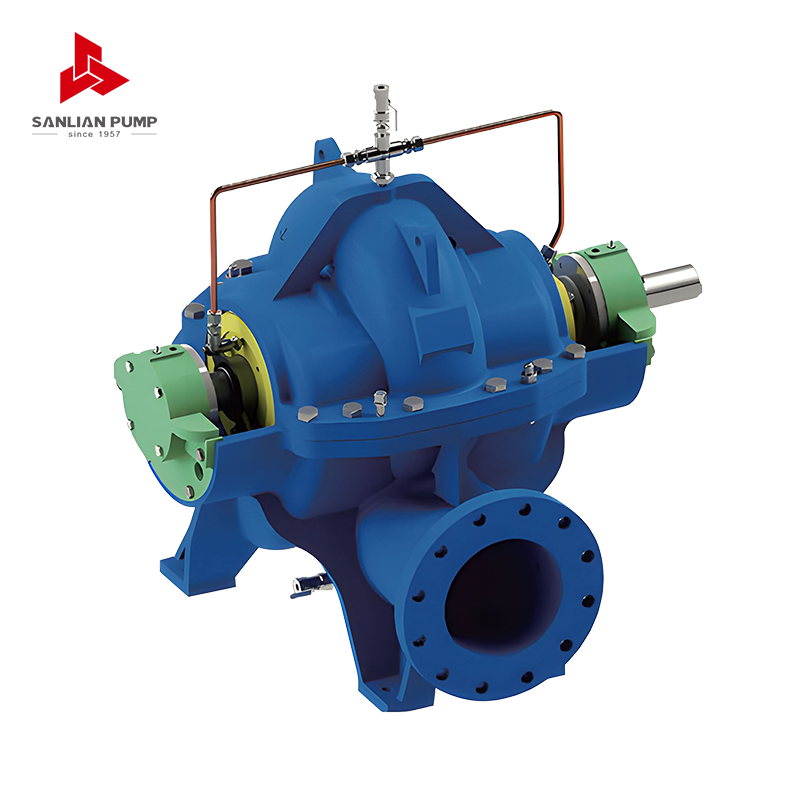

A split-case pump is a type of centrifugal pump characterized by its casing being "split" along a horizontal plane. This design allows the internal components—mainly the impeller, shaft, bearings, and seals—to be accessed and serviced without disturbing the suction or discharge piping.

Split-case pumps are typically double-suction, meaning the fluid enters the impeller from both sides, balancing the hydraulic forces and reducing bearing loads. This feature makes them ideal for high-flow applications where stability and longevity are critical.

Key Components and Design Features

1.Split Casing: The pump housing is divided horizontally, which allows technicians to remove the top half of the casing to access internal components for inspection or maintenance.

2.Double-Suction Impeller: Many split-case pumps feature a double-suction design, which draws fluid into both sides of the impeller, improving hydraulic balance and efficiency.

3.Bearings on Both Sides: Bearings are positioned at both ends of the shaft, which helps reduce deflection, minimize vibration, and extend the life of the pump.

4.Robust Shaft and Seals: The shaft is designed to handle high loads, while the seals (often mechanical seals or packing) prevent leakage under varying pressures and conditions.

Advantages of Using Split-Case Pumps

1. High Efficiency at High Flow Rates

Split-case pumps are designed to handle large volumes of liquid with minimal energy loss. Their double-suction design reduces axial thrust, which allows for smooth and efficient operation even at high capacities.

2. Easy Maintenance and Inspection

The horizontally split casing allows operators to access the internal components without removing the pump from the system. This feature simplifies routine maintenance and reduces downtime, especially in critical systems where every minute counts.

3. Durability and Long Service Life

The balanced design and dual bearing support help prevent wear and tear, extending the pump's service life. These pumps are typically built from cast iron, ductile iron, or stainless steel to withstand demanding operating conditions.

4. Quiet, Low-Vibration Operation

Because the impeller is fed from both sides and the shaft is supported at both ends, split-case pumps run smoothly with less vibration. This makes them suitable for buildings, commercial HVAC systems, and municipal operations where noise control is important.

5. Flexibility in Installation

Split-case pumps can be installed either horizontally or vertically (depending on the model), providing flexibility to accommodate limited space or specific piping arrangements.

6. High Reliability for Critical Systems

These pumps are often used in fire protection, power generation, and municipal water systems where failure is not an option. Their proven design ensures reliability under continuous or heavy-duty operation.

Common Applications

Split-case pumps are widely used in various sectors due to their adaptability and performance:

Municipal Water Supply: Moving large volumes of water from reservoirs to treatment facilities or distribution networks.

HVAC Systems: Circulating chilled and hot water in commercial buildings and industrial facilities.

Firefighting Systems: Providing steady, reliable water pressure in fire suppression systems.

Irrigation and Agriculture: Pumping water for irrigation over large land areas.

Industrial Cooling: Supporting cooling loops in manufacturing, refineries, and power plants.

Flood Control and Drainage: Moving large volumes of water during flood events or stormwater management.

Considerations When Choosing a Split-Case Pump

While split-case pumps offer many advantages, it's important to assess certain factors before selection:

System Flow Rate and Head: Ensure the pump meets the specific hydraulic requirements of your system.

Fluid Type: Consider the fluid's temperature, viscosity, and chemical composition. Some fluids may require special materials for impellers or seals.

Space Constraints: Although compact for their flow capabilities, split-case pumps still require room for maintenance access.

Initial Cost vs. Lifecycle Cost: While split-case pumps may have a higher upfront cost, their efficiency and durability often lead to lower total cost of ownership over time.

Conclusion

Split-case pumps are a tried-and-true solution for handling high flow volumes with exceptional efficiency and durability. Their horizontally split casing, double-suction impeller, and service-friendly design make them a smart choice for critical applications where performance, reliability, and ease of maintenance are top priorities.

If you're seeking a pump that combines power, precision, and practicality, a split-case pump offers a well-balanced solution across many industries and system requirements. Whether for municipal waterworks, industrial facilities, or large commercial buildings, these pumps continue to be a backbone of high-volume fluid transport.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号