Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

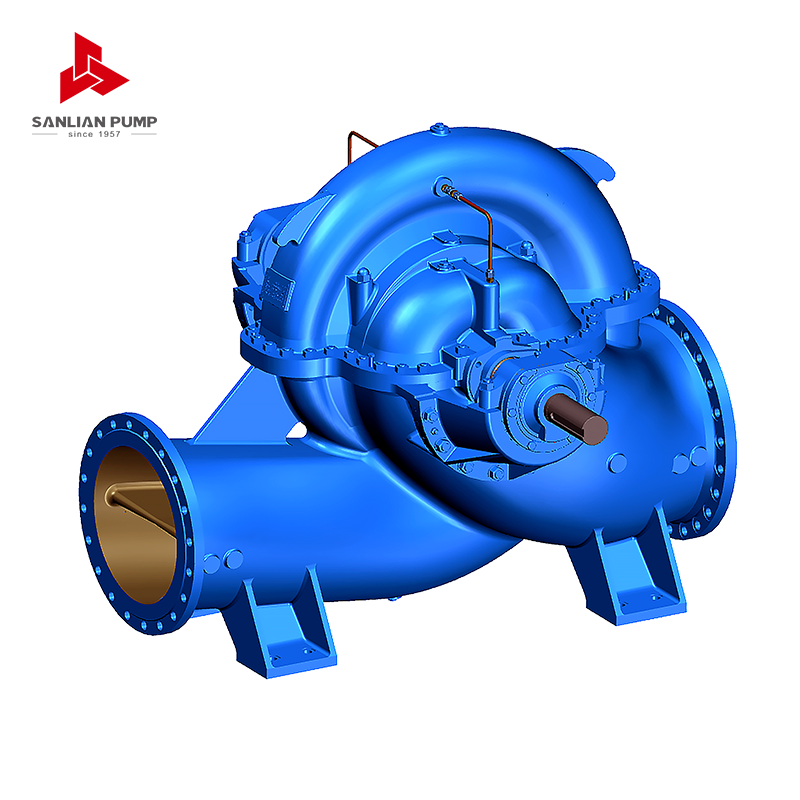

Efficiency and Reliability Advantages of Split Case Pumps in Large-Scale Fluid Systems

Overview of Split Case Pumps and Their Application Scope

Split case pumps are engineered for medium to large-volume fluid transfer environments where stability, service life, and energy performance matter. They are widely adopted in municipal water supply, HVAC chilled water loops, fire protection systems, power plant circulation, and industrial process water transport. Their horizontal split casing allows convenient internal access, which directly supports long-term operation schedules and predictable servicing cycles in large mechanical facilities.

Structural Advantages that Support Operational Stability

A defining feature of split case pumps is the horizontally split housing design, enabling technicians to inspect internal impellers, bearings, and shafts without disconnecting pipelines. This construction reduces maintenance downtime and preserves system integrity during routine checks. Meanwhile, the dual-suction impeller layout provides balanced hydraulic forces, minimizing shaft deflection and vibration during full-load operation.

Key Structural Benefits

- Balanced impeller forces reduce bearing wear and extend mechanical lifetime

- Horizontal split casing simplifies internal inspections and servicing

- Rigid chassis and shaft design maintain alignment under high pressure and heavy load

High Efficiency for Continuous and Large Flow Demands

Energy usage in large pumping systems influences operating budgets, especially in municipal water networks and central cooling installations. Split case pumps support high hydraulic efficiency through a symmetrical inlet structure that minimizes turbulence and reduces energy loss. This makes them suitable for 24-hour circulation systems or applications requiring constant supply and pressure stability.

Performance Comparison Table

| Feature | Split Case Pump | Standard End Suction Pump |

| Energy Efficiency | Higher due to balanced flow and low turbulence | Moderate |

| Maintenance Accessibility | Accessible without pipeline removal | Requires pipe disassembly |

| Flow Capacity | Suitable for high flow | More limited |

Long-Term Reliability and Cost Handling Advantages

Over extended operational cycles, split case pumps help facility operators reduce maintenance-related shutdowns and replacement frequency. Bearings are positioned to work under balanced load conditions, and the hydraulic symmetry limits mechanical fatigue. This long-service behavior is valuable in environments where flow interruptions affect production, municipal supply, or fire system readiness.

Operational Cost Advantages

- Reduced maintenance time supports consistent system uptime for industrial and municipal use

- Extended bearing and shaft lifespan reduces replacement part cycles

- Stable hydraulic performance lowers overall power consumption in high-duty systems

Application Scenarios Where Split Case Pumps Deliver Value

These pumps support environments with constant high-demand fluid circulation or safety-critical water supply. They appear in chilled water loops in large commercial buildings, city water transfer stations, central heating units, fire protection systems, and industrial processing lines. Their robust structure and predictable flow performance make them a dependable choice for system designers and facility engineers targeting stability and operational longevity.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号