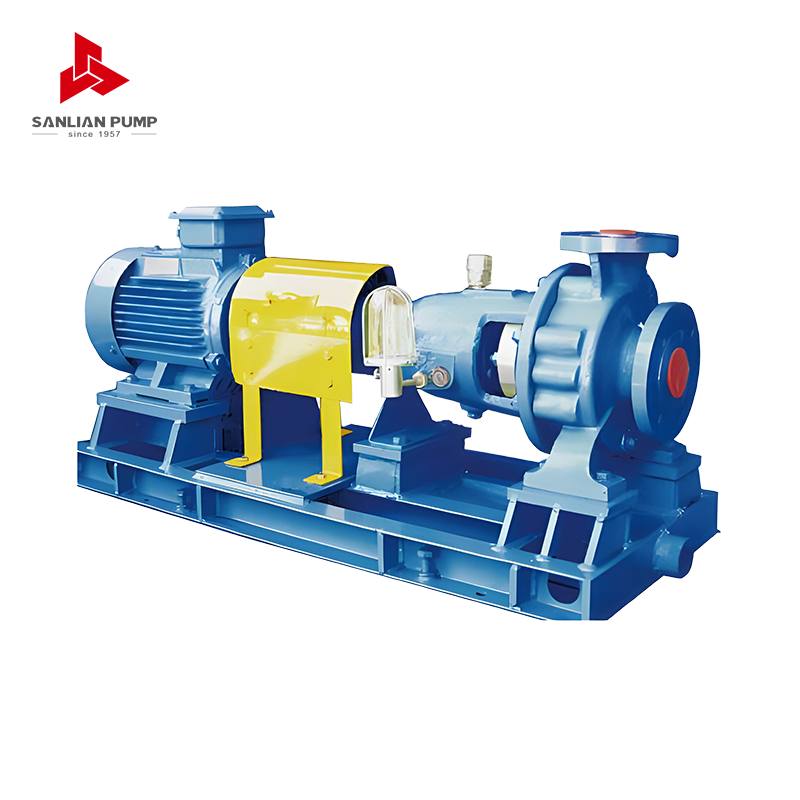

Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

What are the most effective ways to enhance the energy efficiency of chemical pumps in continuous process industries?

The importance of energy efficiency in chemical pumps

Chemical pumps are vital to continuous process industries, operating nonstop to transfer acids, solvents, slurries, and other reactive materials between reactors, storage, and utility systems. Because they run continuously, even small efficiency improvements deliver significant reductions in operating costs and carbon footprint. Enhancing the energy efficiency of chemical pumps requires a systems-level approach combining design, control, maintenance, and monitoring.

Selecting the optimal chemical pump type and size

Proper selection is the foundation for achieving high energy efficiency. Oversized or mismatched chemical pumps often operate far from their best efficiency point (BEP), wasting energy and shortening service life. Engineers must consider chemical compatibility, viscosity, temperature, and the system curve when selecting centrifugal, magnetic drive, or positive displacement pumps.

Key actions for better selection

- Select chemical pumps whose BEP coincides with the plant’s typical operating flow and pressure.

- For corrosive or hazardous fluids, magnetic drive or sealless chemical pumps prevent leaks and maintain efficiency by reducing seal friction losses.

- Avoid oversizing by modeling the entire process curve rather than using maximum flow conditions alone.

Implementing variable speed drives for chemical pumps

Chemical plants often use throttling valves to control flow, but this wastes power. Installing variable speed drives (VFDs) on chemical pumps aligns speed with real-time process demand, reducing power consumption and mechanical stress. Since pump power varies roughly with the cube of speed, even modest speed reductions yield large energy savings.

Practical control improvements

- Integrate VFDs with process control systems to automatically adjust pump speed based on flow, pressure, or level sensors.

- Use multi-pump sequencing to distribute demand across several smaller chemical pumps, keeping each unit near its BEP.

- Set acceleration ramps and protection logic to handle viscous or reactive fluids safely.

Optimizing hydraulic design and piping layout

The energy required to move chemicals depends not only on pump efficiency but also on system hydraulics. High friction losses, abrupt elbows, and undersized pipelines increase discharge pressure and drive up energy consumption. Optimizing piping for chemical pumps directly reduces power demand and extends pump life.

Hydraulic optimization measures

- Recalculate line sizes to minimize velocity and friction losses while maintaining chemical compatibility of materials.

- Replace restrictive valves with full-port options to reduce pressure drops across chemical transfer lines.

- Avoid sharp elbows near suction inlets to maintain stable flow and prevent cavitation.

Improving mechanical and sealing efficiency

For chemical pumps, seal and bearing design strongly affects both safety and energy use. Traditional packed glands and worn mechanical seals generate friction and leaks, wasting power and causing chemical losses. Using advanced sealing and alignment practices reduces mechanical losses and energy draw.

- Upgrade to mechanical or magnetic drive seals that minimize friction while maintaining containment of hazardous chemicals.

- Perform precision shaft alignment to eliminate side loads on bearings and couplings.

- Use energy-efficient bearings designed for chemical environments with aggressive vapors or high temperatures.

Preventing cavitation in chemical pumping systems

Cavitation not only reduces hydraulic efficiency but also damages impellers and surfaces, leading to higher energy consumption. Continuous chemical processes often involve volatile liquids, making NPSH management critical for long-term efficiency.

- Maintain adequate suction head by minimizing suction lift and friction in inlet lines.

- Keep operating points within recommended flow ranges to prevent vapor bubble formation in chemical pumps.

- Monitor vibration and acoustic signatures for early cavitation detection.

Monitoring and predictive maintenance for energy optimization

Continuous monitoring turns chemical pump data into energy-saving insights. Tracking flow, pressure, power, and vibration identifies inefficiencies long before failures occur. Condition-based maintenance reduces downtime and energy loss from degraded components.

Key performance indicators

- Specific energy consumption (kWh per cubic meter pumped).

- Pump hydraulic efficiency trends compared to nameplate performance.

- Vibration amplitude and temperature as indicators of bearing or seal wear.

Retrofits and system-level upgrades

When replacement is not feasible, energy efficiency can still be enhanced through impeller trimming, system rebalancing, and control modernization. These upgrades are particularly valuable for chemical pumps that operate continuously in legacy plants.

| Retrofit Option | Energy Saving Potential | Notes |

| Impeller trimming for chemical pumps | 5–20% | Matches pump to real duty conditions; low capital cost |

| VFD installation and automation integration | 20–60% | Major impact in variable-flow processes |

| Seal and bearing upgrades | 2–10% | Improves both safety and efficiency |

Sustainable operation and long-term benefits

For continuous chemical plants, energy-efficient pumping systems not only lower utility costs but also support sustainability and compliance goals. Upgrading chemical pumps with advanced controls and efficient components strengthens reliability, reduces emissions, and stabilizes production.

An integrated strategy — right-sizing, smart controls, hydraulic optimization, sealing improvements, and real-time monitoring — delivers lasting performance improvements. As chemical processes evolve toward higher automation and energy awareness, efficient chemical pumps will remain central to achieving both operational excellence and environmental responsibility.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号