Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

What applications benefit most from using multistage pumps over single-stage pumps?

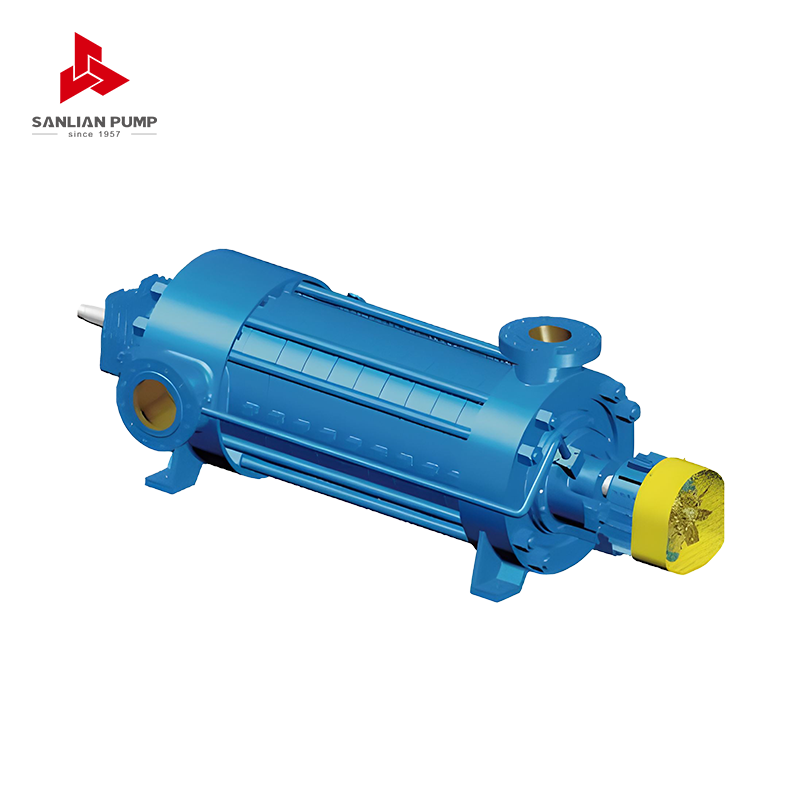

Multistage pumps are designed with multiple impellers in series, enabling them to generate higher pressures than single-stage pumps. Their ability to deliver consistent flow under high pressure makes them ideal for industrial and municipal applications where efficiency, reliability, and long-distance fluid transport are critical.

High-pressure water supply systems

Municipal water systems, high-rise building water supply, and industrial process plants benefit significantly from multistage pumps. By increasing the number of impellers, these pumps can maintain sufficient pressure for vertical or long-distance water distribution while ensuring stable flow rates. Single-stage pumps often cannot achieve the required pressure without oversizing, which increases energy consumption and equipment footprint.

High-rise building applications

In tall structures, water must be delivered to upper floors at adequate pressure. Multistage pumps allow building managers to maintain uniform pressure without using multiple pumps or booster stations. This reduces complexity and maintenance requirements while ensuring comfort and safety for occupants.

Boiler feed and power generation

Power plants rely on multistage pumps to feed high-pressure boilers. The multiple impellers provide the required pressure to push water through high-temperature, high-pressure steam systems efficiently. Single-stage pumps cannot handle the extreme pressure demands of modern boiler systems without excessive size and energy use.

Advantages for thermal power plants

Multistage pumps offer precise flow control, reduced vibration, and reliability under continuous operation, which is essential for thermal power plants. The staged design distributes the pressure increase across several impellers, minimizing wear and extending service life.

Industrial process applications

Industries such as chemical processing, oil and gas, and pulp & paper use multistage pumps for transferring liquids over long distances or against high system pressures. Their ability to handle corrosive or high-viscosity fluids while maintaining pressure makes them superior to single-stage pumps in demanding industrial environments.

Long-distance fluid transfer

Pipeline systems often require consistent pressure across hundreds of meters or kilometers. Multistage pumps can achieve the necessary boost without multiple pump stations, reducing installation and operational costs while simplifying system design.

Desalination and water treatment plants

In desalination and reverse osmosis systems, high-pressure pumps are essential for pushing seawater through membranes. Multistage pumps provide the pressure and efficiency required for continuous operation while reducing wear and energy consumption compared to oversized single-stage pumps.

High-pressure cleaning and firefighting systems

Firefighting and industrial cleaning applications often demand high-pressure water jets. Multistage pumps allow compact and reliable equipment to produce high pressures without excessive power consumption or large mechanical systems. They outperform single-stage pumps where high pressure is mandatory for safety and performance.

Comparison of multistage and single-stage pumps

| Feature | Single-stage Pump | Multistage Pump |

| Max pressure | Moderate | High |

| Flow control | Limited | Flexible |

| Efficiency in high-pressure systems | Low | High |

| Maintenance frequency | Higher | Lower |

Conclusion

Multistage pumps excel in applications requiring high pressure, long-distance fluid transfer, or continuous operation under demanding conditions. From municipal water supply to industrial processes, boiler feed, and desalination, these pumps offer superior performance, energy efficiency, and reliability compared to single-stage pumps. Selecting the appropriate multistage pump ensures operational stability, reduced maintenance, and optimized system efficiency.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号