Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

The Advantages of End Suction Centrifugal Pumps for Water and Wastewater Treatment

The Role of End Suction Centrifugal Pumps in Water and Wastewater Treatment

End suction centrifugal pumps are a cornerstone of fluid handling systems, particularly in water and wastewater treatment facilities. These pumps are designed to move large volumes of water or wastewater efficiently and reliably, ensuring that treatment processes run smoothly. Due to their simple design, reliability, and efficiency, end suction centrifugal pumps are widely used in various water treatment plants, sewage systems, and industrial applications. In this article, we will explore the key advantages of end suction centrifugal pumps in water and wastewater treatment.

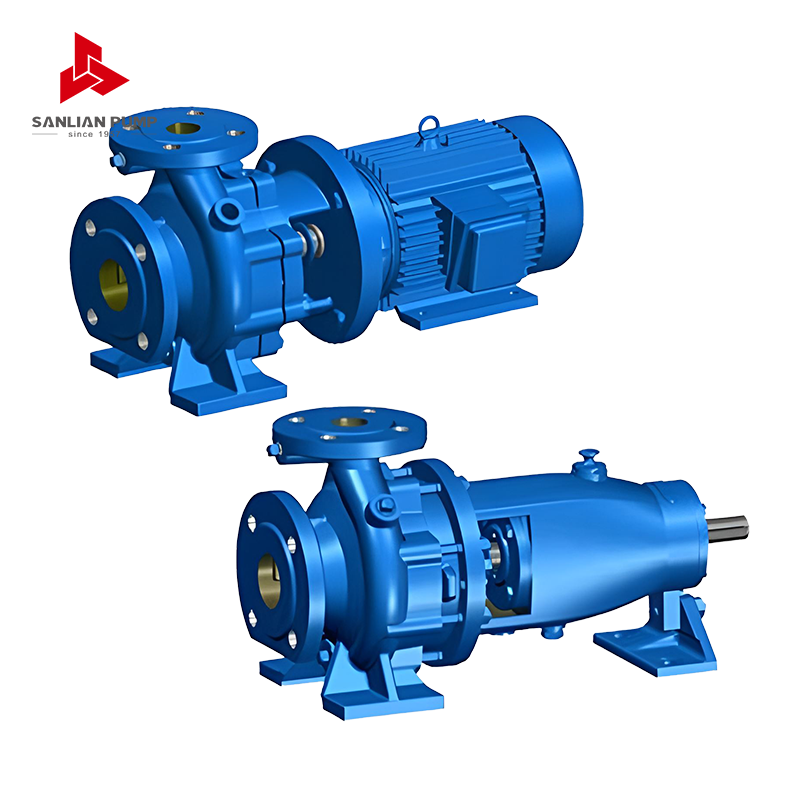

What Are End Suction Centrifugal Pumps?

End suction centrifugal pumps are commonly used for transporting water and other fluids in a variety of industries. These pumps operate by converting rotational energy from the impeller into kinetic energy, which then increases the pressure and moves the fluid through the pump. The term "end suction" refers to the configuration where the suction inlet is located at the end of the pump, opposite to the discharge outlet. This design offers several benefits, especially for water and wastewater treatment systems where high flow rates and consistent performance are crucial.

Key Advantages of End Suction Centrifugal Pumps in Water and Wastewater Treatment

End suction centrifugal pumps offer several advantages for water and wastewater treatment, making them a popular choice for both municipal and industrial applications. Below are some of the key benefits of using these pumps in water treatment systems:

High Efficiency and Reliability

One of the primary benefits of end suction centrifugal pumps is their high efficiency and reliable performance. These pumps are capable of handling large volumes of water or wastewater with minimal energy consumption, which is essential for maintaining the cost-effectiveness of treatment plants. Their simple design means fewer moving parts, which translates into lower wear and tear, making them highly reliable over time.

Furthermore, end suction pumps are known for their ability to deliver consistent flow rates, even in challenging conditions. This is especially important in water treatment processes that require steady and uninterrupted water flow for optimal performance.

Space-Saving Design

End suction centrifugal pumps are designed with a compact footprint, making them an ideal choice for facilities with limited space. Their single-stage, horizontal configuration allows for easy installation and integration into existing systems without taking up excessive space. This is particularly advantageous in water and wastewater treatment plants, where space optimization is often a key consideration.

Ease of Maintenance

Maintenance is crucial for the smooth operation of water and wastewater treatment plants, and end suction centrifugal pumps are designed with easy access to components that require routine servicing. With fewer parts and simpler mechanics than other types of pumps, these pumps are relatively easy to maintain and repair, which helps minimize downtime and reduce maintenance costs.

Routine maintenance tasks such as cleaning, lubrication, and part replacements can be performed quickly and efficiently, helping to maintain the pump's longevity and reliability.

Durability in Harsh Conditions

Water and wastewater treatment often involve harsh conditions, including the presence of abrasive particles, corrosive chemicals, and varying temperatures. End suction centrifugal pumps are designed to withstand these challenging environments. With the option to use corrosion-resistant materials such as stainless steel or composite materials, these pumps can operate effectively in both freshwater and wastewater treatment applications, even when dealing with challenging fluids.

Cost-Effectiveness

End suction centrifugal pumps are typically more affordable than other types of pumps, particularly in terms of both initial purchase and operational costs. Their simplicity and efficient design reduce both capital investment and ongoing operational expenses. Additionally, their low maintenance requirements and long service life contribute to long-term cost savings, making them a cost-effective solution for water and wastewater treatment facilities.

Applications in Water and Wastewater Treatment

End suction centrifugal pumps are used in a wide variety of applications within water and wastewater treatment. Some of the most common applications include:

Municipal Water Treatment Plants

- Pumping raw water from rivers, lakes, or reservoirs to filtration systems.

- Transporting treated water to distribution systems.

Wastewater Treatment Plants

- Pumping sewage water for primary and secondary treatment stages.

- Handling effluent and sludge removal processes.

Industrial Water Systems

- Supporting cooling water systems in power plants and manufacturing facilities.

- Providing water circulation for chemical processing or other industrial applications.

Conclusion: Why Choose End Suction Centrifugal Pumps for Water and Wastewater Treatment

End suction centrifugal pumps are an excellent choice for water and wastewater treatment applications due to their reliability, efficiency, and cost-effectiveness. Their simple design, ease of maintenance, and ability to handle harsh conditions make them ideal for both municipal and industrial treatment facilities. With their ability to deliver consistent performance while minimizing energy consumption and maintenance costs, end suction centrifugal pumps play a critical role in ensuring the smooth operation of water and wastewater treatment systems.

For facilities looking to optimize their pumping systems and reduce operational costs, investing in end suction centrifugal pumps is a practical and efficient solution.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号