Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

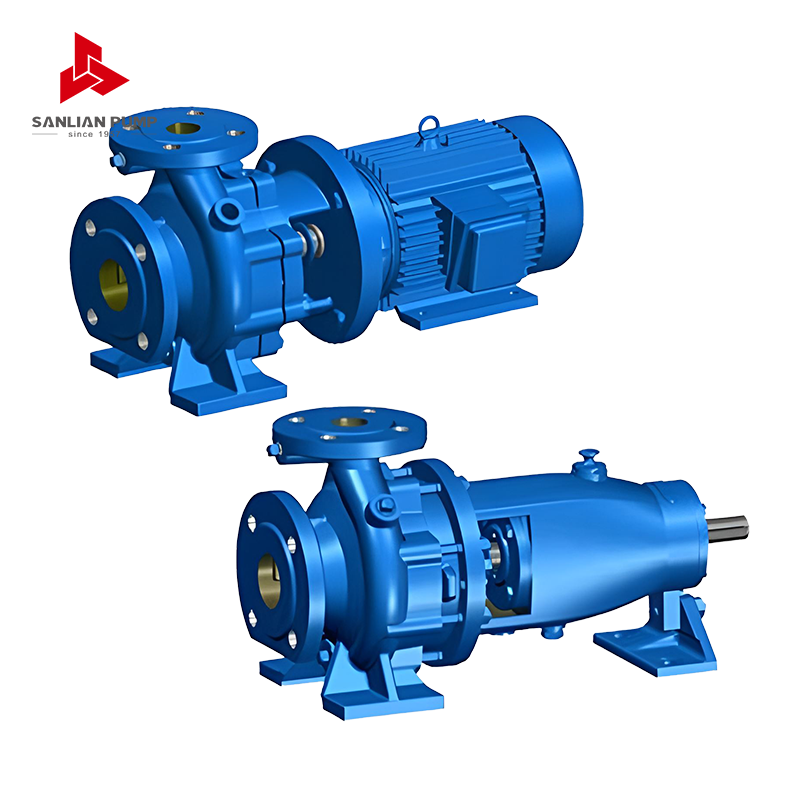

How End Suction Centrifugal Pumps Help Minimize Energy Consumption in Pumps Systems

Energy Efficiency: How End Suction Centrifugal Pumps Make a Difference

Energy consumption in pump systems can be one of the highest operational costs in industries. But did you know that end suction centrifugal pumps are designed to tackle this issue head-on? Their efficient hydraulic design, coupled with advanced features like variable speed drives (VSDs), helps minimize energy usage without compromising on performance. Let’s take a closer look at how these pumps reduce energy consumption and contribute to cost savings in various applications.

Optimizing Fluid Flow with End Suction Centrifugal Pumps

At the heart of every end suction centrifugal pump is the impeller – a simple yet highly effective component. The impeller is designed to convert rotational energy into kinetic energy, propelling fluid through the system. This basic function is optimized in end suction pumps to ensure minimal energy loss. With fewer moving parts and reduced friction, these pumps operate smoothly, leading to less energy consumption.

Why Does This Matter?

- Smooth fluid flow means the pump doesn’t need to work harder than necessary.

- Fewer moving parts reduce the overall energy lost to mechanical resistance.

- Optimized design ensures fluid moves through the system efficiently, cutting down on unnecessary power use.

Variable Speed Drives: The Key to Energy Savings

One of the standout features of modern end suction centrifugal pumps is the incorporation of variable speed drives (VSDs). This technology allows the pump to adjust its speed based on the real-time requirements of the system. By scaling the pump’s output to match demand, energy consumption is kept to a minimum, particularly in systems with fluctuating needs.

The Benefits of Variable Speed Control

- Reduces energy waste by operating the pump only at the necessary speed.

- Prevents the pump from running at full capacity when lower flow rates are required.

- Extends the lifespan of the pump and reduces maintenance by preventing overworking.

The Efficiency of Low Friction Components

High-friction components are one of the biggest energy drains in any pump system. End suction centrifugal pumps are built with minimal friction, thanks to their precision-engineered seals and bearings. These low-friction parts reduce the mechanical resistance that would otherwise demand more power from the motor.

Key Components That Help Save Energy

- Efficient bearings with reduced friction lower energy consumption.

- Corrosion-resistant materials reduce wear and tear, leading to fewer mechanical failures.

- Tightly sealed components prevent energy loss from leaks and excessive heat buildup.

Energy-Saving Examples in Industry

End suction centrifugal pumps are already making a significant impact in industries where energy efficiency is crucial. Let’s look at a few real-world examples where these pumps help reduce energy consumption:

Water Treatment Plants

Water treatment plants need to process large volumes of water. By using end suction pumps with variable speed control, these plants can optimize their energy usage, particularly during off-peak hours or when less water needs to be treated. This minimizes unnecessary power consumption, which translates to lower operational costs.

HVAC Systems

In HVAC systems, energy efficiency is essential to reduce operational costs. End suction pumps with variable speeds can adjust to meet the cooling or heating needs of a building. By operating only when needed and at the right speed, these pumps prevent wasted energy, improving overall system efficiency.

Industrial Fluid Transfer

In industrial applications, such as chemical processing, pumps are required to move fluids through pipelines. By selecting an end suction centrifugal pump, industries can maintain flow rates while optimizing energy use. Whether it’s pumping raw chemicals or processed materials, these pumps reduce the overall power consumption, leading to a more sustainable operation.

Maximizing Savings Through Proper Sizing and Maintenance

To achieve the best energy savings, proper pump sizing is crucial. An undersized pump will have to work harder, while an oversized pump will consume unnecessary energy. Ensuring that the pump is correctly sized for the system’s needs, along with regular maintenance, can prevent energy losses and prolong pump life.

Sizing Tips for Optimal Energy Efficiency

- Conduct a system audit to determine the exact flow requirements before purchasing a pump.

- Ensure that the pump operates within its optimal efficiency range for maximum energy savings.

- Regularly check for leaks, wear, and proper alignment to reduce energy losses.

Conclusion: The Future of Energy-Efficient Pump Systems

End suction centrifugal pumps are not just about fluid transfer; they are about improving energy efficiency. With their ability to optimize flow, reduce friction, and incorporate variable speed control, these pumps are leading the way in energy-saving pump systems. Whether in water treatment, HVAC, or industrial fluid handling, the energy efficiency of end suction pumps plays a critical role in reducing operational costs and minimizing environmental impact. By making the right choice of pump and maintaining it properly, industries can achieve substantial savings, paving the way for more sustainable operations.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号