Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

How does a double-suction split case pump improve hydraulic performance?

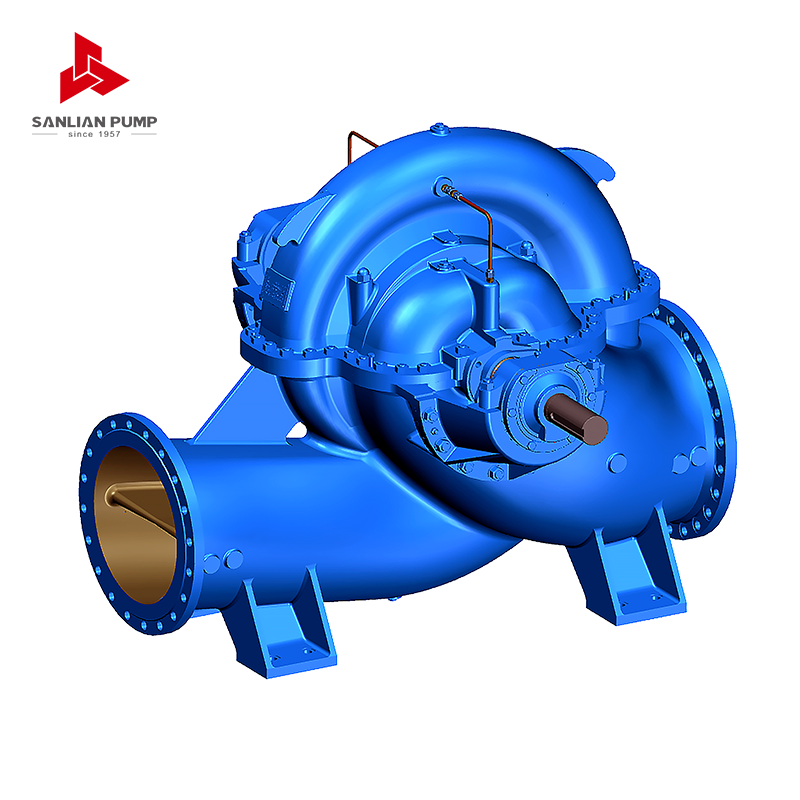

A double-suction split case pump is a specific type of centrifugal pump known for its symmetrical design and ability to handle high flow rates with increased hydraulic efficiency. This design features an impeller that allows water or fluid to enter from both sides simultaneously, offering a number of performance advantages over single-suction or end-suction pump configurations.

1. Balanced Axial Thrust for Reduced Wear

One of the most significant advantages of the double-suction configuration is its ability to balance axial thrust. In single-suction pumps, the fluid enters the impeller from one side, creating a net force along the shaft direction. This axial load puts stress on the bearings and shaft assembly, potentially leading to premature wear and higher maintenance requirements.

In contrast, a double-suction impeller allows fluid to enter from both sides, distributing the hydraulic forces evenly. This symmetrical flow cancels out the axial forces, reducing stress on the shaft and bearings. As a result, the pump experiences less mechanical wear, runs more smoothly, and offers extended service life, which translates to lower operating costs and fewer interruptions for maintenance.

2. Higher Flow Capacity at Lower Speeds

The double-suction design also increases the flow capacity of the pump without necessitating higher rotational speeds or larger impeller diameters. Because water enters from two sides, the impeller can move more fluid with each rotation. This allows for higher flow rates while maintaining relatively low operating speeds, which is beneficial for reducing vibration, noise, and mechanical stress.

Lower speeds also help avoid problems associated with high-speed operation, such as cavitation or excessive heat generation. This makes double-suction split case pumps particularly well-suited for large-scale fluid handling applications such as municipal water distribution, industrial cooling water systems, HVAC plants, and irrigation networks.

3. Enhanced Hydraulic Efficiency

Double-suction pumps typically operate with greater hydraulic efficiency than their single-suction counterparts. The dual-inlet design helps minimize turbulence and recirculation inside the pump, promoting smoother and more streamlined fluid flow through the impeller and volute casing. Reduced internal losses mean that a higher percentage of the mechanical energy input is converted into useful hydraulic energy.

In many cases, double-suction pumps can achieve efficiency ratings exceeding 85%, depending on size, speed, and operating conditions. This makes them a preferred choice in systems where energy consumption and operating cost are major concerns.

4. Improved Stability and Operating Reliability

By virtue of their symmetrical hydraulic design and balanced shaft loading, double-suction split case pumps tend to exhibit more stable and quieter operation. Reduced vibration and better shaft alignment contribute to improved reliability over long operating periods. This is especially important in applications where continuous 24/7 operation is required, such as power plants, desalination facilities, or fire protection systems.

In addition, the split case construction allows for easy access to internal components without disturbing the piping or motor connections. This feature simplifies maintenance and inspection tasks, further enhancing the long-term performance of the pump.

Conclusion

The double-suction split case pump is a high-performance solution that offers numerous hydraulic and mechanical advantages over other centrifugal pump designs. By allowing fluid to enter the impeller from both sides, it balances axial forces, increases flow capacity, improves energy efficiency, and ensures stable, low-maintenance operation. These characteristics make it a reliable and cost-effective choice for a wide range of high-demand fluid transport applications.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号