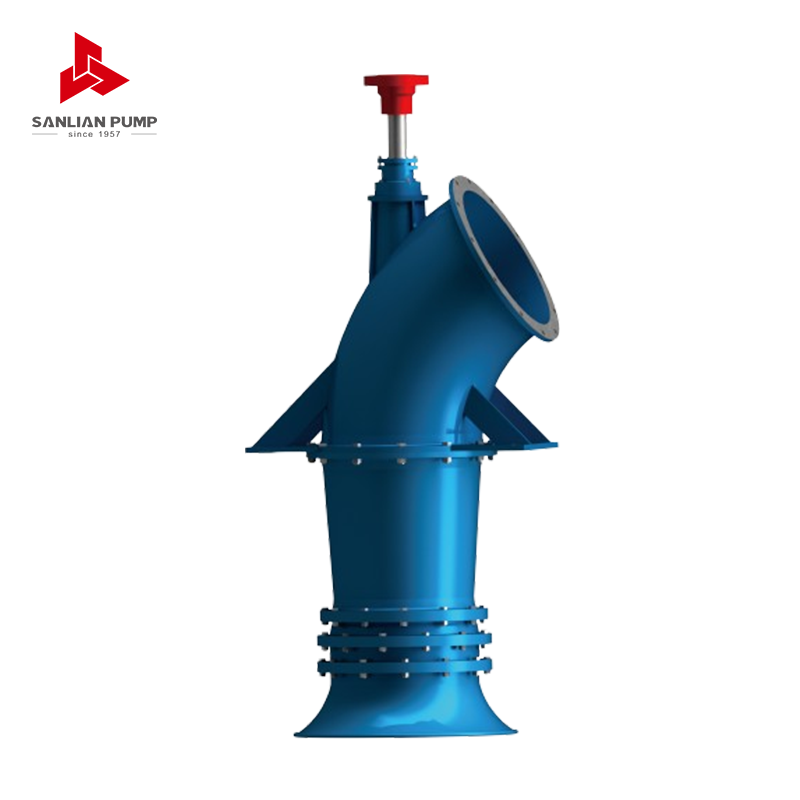

Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

Why are mixed flow pumps preferred for applications involving high flow rates and moderate head?

Mixed flow pumps are preferred for applications involving high flow rates and moderate head because they offer a unique combination of performance characteristics that effectively balance volume delivery and pressure generation. Their impeller design and flow dynamics allow them to operate efficiently in scenarios where neither purely radial nor purely axial pumps would be ideal. Here's a detailed explanation:

1. Balanced Hydraulic Design for Flow and Head

Mixed flow pumps use an impeller that combines features of both radial and axial flow designs. This hybrid design enables the pump to deliver a high volume of fluid (like axial pumps) while still generating a moderate amount of pressure (like radial pumps).

Axial flow pumps move fluid primarily along the shaft direction and are efficient for low-head, high-flow situations.

Radial flow pumps force fluid outward from the center and are used for high-head, low-flow applications.

Mixed flow pumps, in contrast, push fluid both outward and along the shaft axis, resulting in a compromise between flow and pressure—ideal for many real-world water handling needs.

2. Efficient Operation in Open System Applications

Many systems such as irrigation, flood control, municipal drainage, and cooling water circulation require pumping large quantities of water over relatively short vertical distances (i.e., low to moderate head). Mixed flow pumps are engineered to handle large volumes of water at heads typically ranging from 10 to 30 meters, making them particularly well-suited for:

Stormwater removal systems

Flood mitigation projects

Agricultural irrigation

Circulating water in power plants

3. Lower Energy Consumption at Target Operating Conditions

Because mixed flow pumps are optimized for high-flow, moderate-head conditions, they generally operate near their Best Efficiency Point (BEP) in those environments. This means:

Reduced power consumption

Lower operational costs

Less wear on components over time

This energy efficiency becomes particularly important in large-scale systems where pumps run continuously or for extended periods.

4. Compact Design with High Volume Capability

Compared to radial flow pumps capable of similar flow rates, mixed flow pumps typically have smaller and more compact casings, which reduces footprint and installation complexity. Their ability to move large volumes of water without requiring a massive, high-head radial pump helps simplify infrastructure and reduce initial capital costs.

5. Stable Performance Across Operating Conditions

Mixed flow pumps also maintain relatively stable flow under changing system conditions, such as fluctuating water levels or flow demands. This makes them reliable for dynamic environments like:

Tidal or river-based pumping stations

Reservoir drawdown systems

Variable-rate irrigation fields

Summary

| Feature | Benefit |

| Hybrid impeller design | Balances high flow with moderate head |

| Energy-efficient | Lower power usage for volume-dominant tasks |

| Versatile application | Ideal for drainage, irrigation, cooling water, flood control |

| Compact footprint | Easier installation and lower infrastructure costs |

| Stable under varying conditions | Suitable for real-world environmental changes |

In short, mixed flow pumps strike the right balance for applications where moving large amounts of water efficiently is more important than overcoming extreme vertical height, making them a practical and cost-effective solution in many industries.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号