Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

What are the Advantages of Using a Double Suction Impeller in Split Case Pumps?

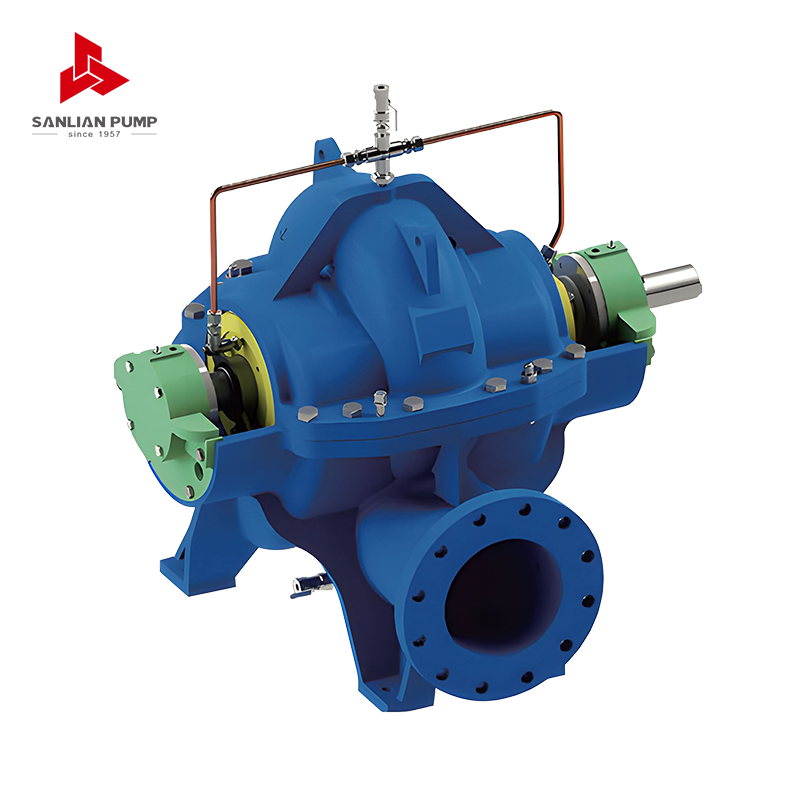

In the world of high-performance pumping systems, efficiency isn’t just a preference—it’s a mandate. Whether you're managing municipal water supply, HVAC systems, fire protection networks, or large-scale industrial processes, the integrity of your pump architecture makes or breaks operational success. Among the array of engineered solutions available, one particular innovation stands out: the double suction impeller in split case pumps. Precision-crafted for optimal hydraulic balance and robust flow management, this configuration has become an industry benchmark.

But what exactly makes the double suction impeller so superior?

Dual Inlet, Singular Advantage

Unlike conventional single-suction impellers, a double suction impeller draws fluid into the eye from both sides simultaneously. This bi-directional flow design offers a significant hydraulic advantage—it balances axial thrust. With forces equalized on either side of the impeller, the load on bearings is drastically reduced. The result? Lower wear, extended equipment life, and dramatically diminished maintenance frequency.

This balance also translates into smooth, vibration-free operation—critical in systems where downtime is not an option.

High Efficiency at Large Flow Rates

Double suction impellers excel at delivering high volumes of fluid with minimal energy input. In split case pumps, this efficiency becomes a defining attribute. The symmetrical flow reduces entrance losses and turbulence, allowing the impeller to operate at peak hydraulic efficiency.

For facilities handling hundreds or thousands of gallons per minute, the long-term energy savings are not marginal—they’re measurable and substantial.

Reduced NPSH Requirements

Net Positive Suction Head (NPSH) is often the Achilles' heel in high-capacity pumping systems. Cavitation is the silent saboteur that eats away at performance and longevity. The double suction design inherently lowers the NPSH requirement. Fluid enters the impeller from both sides, reducing velocity at entry and minimizing the risk of vapor pocket formation. In low-lift or high-suction applications, this can be the difference between persistent failure and dependable service.

Superior Reliability in Demanding Applications

From the arid demands of irrigation systems to the punishing rigor of industrial water transfer, reliability is non-negotiable. A double suction impeller, housed within a split case configuration, offers mechanical simplicity and maintenance access that’s both fast and safe. With the split case design, there's no need to disturb suction and discharge piping for internal inspections—saving labor and reducing downtime.

This is especially advantageous in critical infrastructure, where a few hours offline could cascade into significant operational and financial losses.

Engineering Excellence, Delivered

Behind every exceptional pump is an engineering philosophy rooted in performance, durability, and precision. At [Company Name], we don’t just supply pumps—we design systems that redefine standards. Our split case pumps, equipped with double suction impellers, are the product of rigorous design, computational fluid dynamics analysis, and materials selected to withstand the harshest conditions.

As a trusted partner to municipal, commercial, and industrial clients worldwide, our solutions deliver more than flow—they deliver confidence. From consultation to commissioning, our focus remains steadfast: maximizing uptime, reducing total cost of ownership, and supporting the mission-critical operations of our clients.

The double suction impeller in a split case pump isn’t just an option—it’s a strategic advantage. With its unparalleled hydraulic balance, energy efficiency, reduced NPSH requirements, and serviceability, this configuration stands as a testament to smart engineering.

In a landscape where every drop, every dollar, and every decision matters, investing in superior pump technology isn’t a luxury—it’s a necessity. Partner with a provider who understands the stakes and delivers beyond expectation.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号