Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

What are the main advantages of using split case pumps in water supply systems?

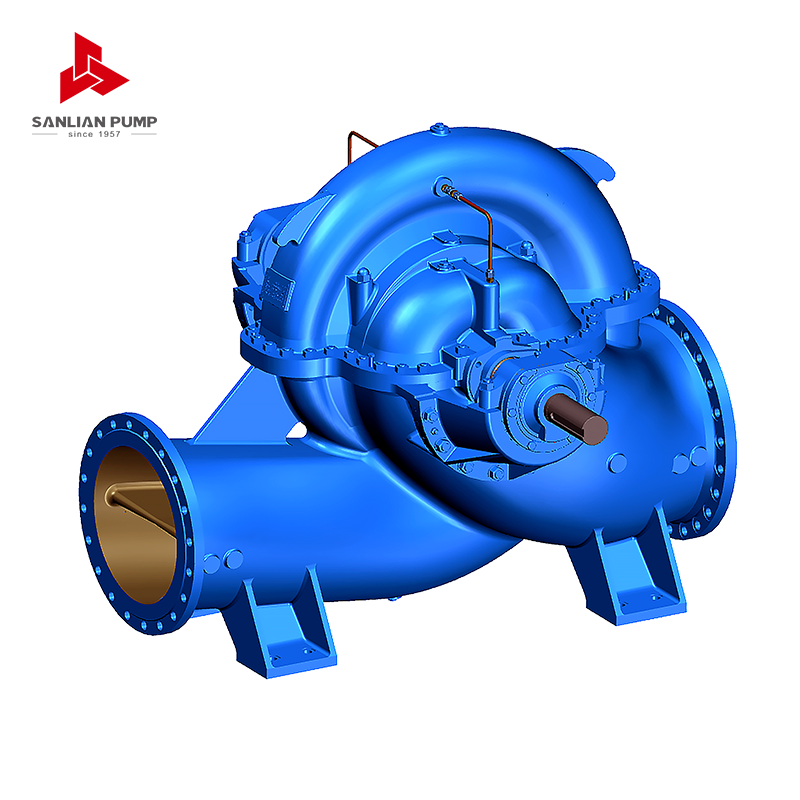

Split case pumps are widely recognized and utilized in water supply systems for their efficiency, reliability, and ease of maintenance. Their distinctive design and operational features make them particularly well-suited for delivering large volumes of water in municipal, industrial, and agricultural applications. Understanding the main advantages of using split case pumps in water supply systems sheds light on why they are often the preferred choice for such critical infrastructure.

A fundamental advantage of split case pumps is their robust construction, which allows them to handle high flow rates with relatively low maintenance. The split case design means the pump casing is divided into two parts — typically a top and bottom half — which are bolted together. This configuration provides easy access to the internal components such as the impeller, shaft, and bearings without disturbing the pipe connections or the motor alignment. In practical terms, this means maintenance, inspection, and repairs can be conducted more quickly and cost-effectively compared to other pump types where disassembly may require removing the entire unit.

Split case pumps also typically feature double suction impellers, which allow water to enter the impeller from both sides. This balanced suction reduces axial thrust on the pump shaft, resulting in smoother operation and less wear on bearings and seals. For water supply systems that require continuous and reliable operation, this contributes to increased pump lifespan and reduced downtime. The balanced hydraulic forces also translate into better overall pump efficiency, which is critical for large-scale water distribution where energy consumption can be substantial.

Another significant advantage is their high efficiency at varying flow rates. Split case pumps maintain efficient performance across a wide operating range, meaning they can effectively adapt to the fluctuating demand typical of municipal water systems. Whether the system is operating near full capacity during peak hours or at reduced flow during off-peak times, split case pumps continue to deliver water efficiently. This flexibility translates into energy savings and improved sustainability, which are key considerations for modern water utilities aiming to reduce operational costs and environmental impact.

The design of split case pumps also allows for large capacity and high pressure delivery. Their impellers are designed to move substantial volumes of water, making them suitable for applications like city water supply, irrigation, industrial cooling, and fire protection systems. The ability to handle both high flow and moderate to high pressures means that a single pump can replace multiple smaller units, simplifying the overall system design and reducing installation costs.

Additionally, split case pumps are known for their reliable sealing systems, which are essential to prevent leakage and maintain system integrity. In water supply systems, maintaining water quality and avoiding contamination are paramount. The mechanical seals and gland packing used in these pumps are designed to minimize leakage and withstand continuous operation in a variety of water conditions. Some models also include features such as seal flush plans and cooling systems to extend seal life under demanding conditions.

From a practical standpoint, the modular nature of split case pumps means that parts can often be replaced individually rather than requiring complete pump replacement. This modularity, combined with their robust design, allows water utilities to keep spare parts in stock and perform on-site repairs with minimal disruption to service. For infrastructure that serves large populations or critical industries, this reliability and ease of maintenance are invaluable.

Another advantage is the quiet operation of split case pumps. Their balanced hydraulic design and precise engineering reduce vibration and noise levels during operation, which can be important in urban or residential areas where noise pollution must be controlled. This contributes to better working conditions for maintenance personnel and less disturbance to the surrounding community.

The main advantages of using split case pumps in water supply systems include their robust and service-friendly construction, high efficiency and reliability, ability to handle large volumes and pressures, effective sealing to prevent leaks, and quiet operation. These factors combine to make split case pumps a cost-effective, durable, and energy-efficient solution for delivering clean water in municipal and industrial settings. Their design and performance characteristics help ensure uninterrupted water supply, reduce operating costs, and support long-term sustainability goals for water utilities worldwide.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号