Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

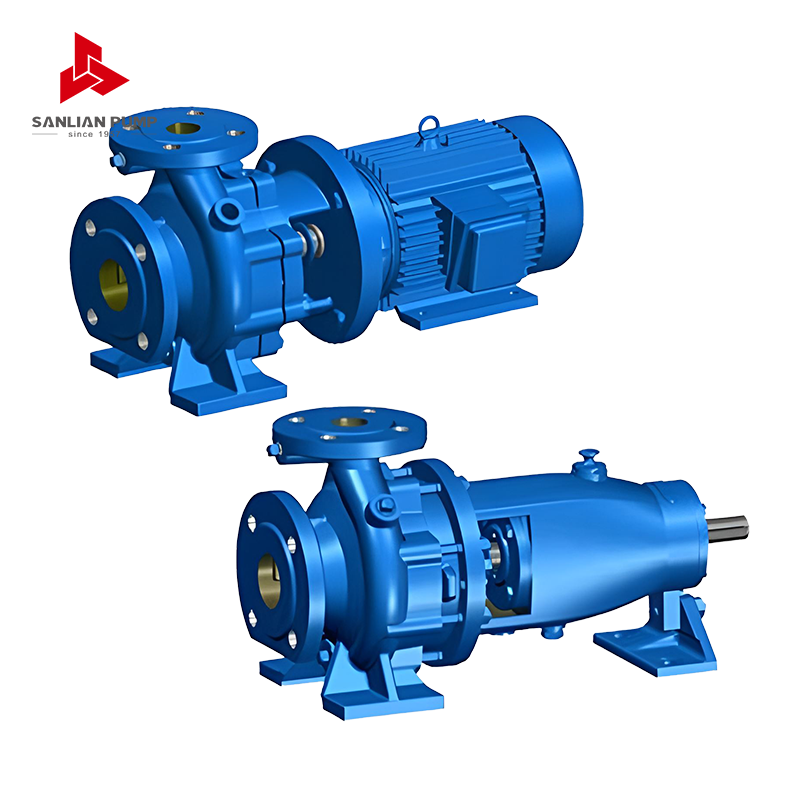

End Suction Centrifugal Pumps: Design, Operation, Selection and Maintenance Guide

Working Principle of End Suction Centrifugal Pumps

End suction centrifugal pumps are single-stage pumps in which liquid enters the impeller axially through the suction nozzle and exits radially through the discharge outlet. The design is compact and mechanically straightforward. When the motor drives the impeller to rotate at high speed, centrifugal force pushes the fluid outward from the impeller eye to the volute casing. This movement converts mechanical energy into kinetic energy and then into pressure energy within the casing.

Because of this direct flow path, end suction centrifugal pumps are widely used in water supply systems, HVAC circulation, industrial process transfer, irrigation, and fire protection. Their performance depends heavily on impeller diameter, rotational speed, and system resistance. Matching pump curves to system requirements is essential to maintain efficiency and avoid cavitation.

Structural Components and Design Features

The simplicity of end suction centrifugal pumps does not reduce their engineering precision. Each component plays a defined role in performance and durability.

Impeller and Volute Casing

The impeller is typically closed or semi-open, depending on the application. Closed impellers are preferred for clean water systems due to higher hydraulic efficiency. Semi-open designs tolerate limited solids. The volute casing surrounds the impeller and gradually expands to convert velocity into pressure. Proper casing geometry ensures stable hydraulic performance across operating ranges.

Shaft, Bearings and Mechanical Seal

The pump shaft connects the impeller to the motor. Bearings support radial and axial loads to maintain alignment during operation. Mechanical seals prevent leakage at the shaft penetration point. Seal selection depends on fluid temperature, pressure, and chemical properties. In industrial systems, double mechanical seals may be used when handling aggressive media.

Common Construction Materials

- Cast iron for general water transfer applications

- Stainless steel for corrosion resistance in chemical or food processes

- Bronze impellers for improved wear resistance

- Duplex alloys for high-pressure or marine environments

Performance Characteristics and Pump Curves

Understanding pump curves is critical when selecting end suction centrifugal pumps. The performance curve illustrates the relationship between flow rate, head, efficiency, and power consumption. The best efficiency point is the operating condition where hydraulic losses are minimized. Running the pump too far from this point can increase vibration, reduce seal life, and waste energy.

Net positive suction head required is another essential parameter. If available suction pressure is insufficient, cavitation can occur. Cavitation produces vapor bubbles that collapse inside the impeller, leading to erosion and noise. Proper suction piping design and correct pump elevation help maintain adequate suction conditions.

Selection Criteria for Industrial and Commercial Use

Selecting end suction centrifugal pumps involves more than matching flow and head requirements. Engineers must evaluate system layout, fluid characteristics, and operational demands.

Key Parameters to Evaluate

- Required flow rate under peak demand

- Total dynamic head including friction losses

- Fluid temperature and viscosity

- Chemical compatibility with pump materials

- Motor efficiency and available power supply

Variable frequency drives are increasingly used with end suction centrifugal pumps. By adjusting motor speed, operators can match output to demand and reduce energy consumption in part-load conditions.

Installation and Alignment Best Practices

Proper installation directly influences pump reliability. The baseplate must be level and securely anchored. Misalignment between motor and pump shaft leads to premature bearing failure. Flexible couplings help compensate for minor movement but do not replace accurate alignment procedures.

Suction piping should be straight and adequately sized to minimize turbulence. Installing a suction strainer protects the impeller from debris. Discharge piping should include isolation valves and pressure gauges to monitor operating conditions. Ensuring that the pump is primed before startup prevents dry running and mechanical seal damage.

Maintenance Strategies to Extend Service Life

Routine inspection and predictive maintenance reduce downtime. Operators should monitor vibration levels, bearing temperature, and seal leakage. Lubrication schedules must follow manufacturer recommendations. Replacing worn wear rings maintains hydraulic efficiency and reduces internal recirculation losses.

In high-demand systems such as fire protection or municipal water supply, maintaining standby units ensures operational continuity. Recording performance data over time allows early detection of efficiency loss or internal wear.

Typical Applications of End Suction Centrifugal Pumps

| Application Area | Primary Function | Operating Characteristics |

| HVAC Systems | Chilled and hot water circulation | Continuous moderate flow |

| Water Supply | Pressure boosting | Variable demand |

| Industrial Processing | Fluid transfer and cooling | High reliability requirement |

| Irrigation | Water distribution | Outdoor continuous operation |

End suction centrifugal pumps remain one of the most versatile pump types due to their straightforward structure, reliable hydraulic performance, and adaptability to different industries. By carefully selecting, installing, and maintaining these pumps, operators can achieve stable flow control and long-term operational efficiency across a wide range of applications.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号