Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

Submersible Pump Repair: How to Fix Submersible Pump Issues and Understand Continuous Run Time

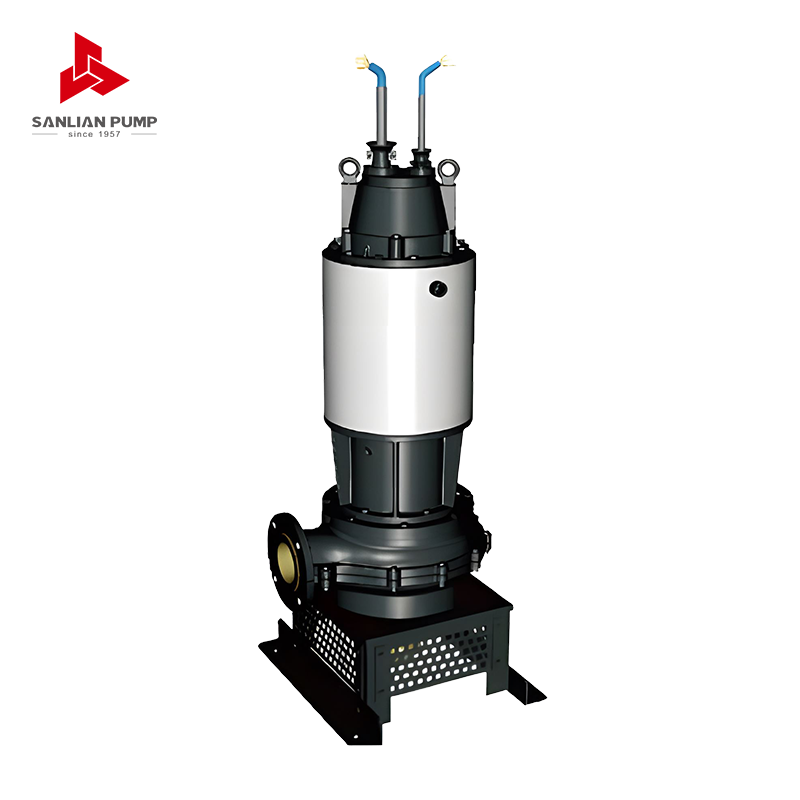

Submersible pumps are widely used in wells, drainage systems, wastewater handling, and industrial applications due to their ability to operate efficiently while fully submerged. Despite their robust design, failures can still occur over time, making submersible pump repair an important topic for operators and maintenance teams. Understanding how to fix submersible pump problems and knowing how long a submersible pump can run continuously are essential for maintaining stable operation and avoiding unexpected downtime.

This article focuses on practical repair considerations, common fault scenarios, and operating limits related to continuous operation. The goal is to help users diagnose issues accurately and apply effective repair strategies based on real operating conditions.

Common Reasons for Submersible Pump Failure

Before attempting to fix submersible pump issues, it is important to identify the root causes of failure. Submersible pumps operate in demanding environments where electrical, mechanical, and hydraulic stresses are constantly present. Failures often result from a combination of these factors rather than a single isolated issue.

- Motor overheating caused by insufficient cooling or dry running

- Seal failure allowing water or slurry to enter the motor housing

- Electrical faults such as insulation breakdown or cable damage

- Impeller wear or blockage due to solids, sand, or debris

- Bearing wear caused by misalignment or long-term continuous operation

Key Steps in Submersible Pump Repair

Effective submersible pump repair follows a structured process rather than trial-and-error adjustments. Proper inspection, disassembly, and testing are essential to avoid recurring failures after the pump is returned to service.

Inspection and Fault Diagnosis

The first step in any repair process is a detailed inspection. Electrical resistance testing, insulation checks, and visual examination of cables help identify electrical problems. Mechanical inspection focuses on impeller condition, shaft alignment, bearing smoothness, and seal integrity.

Replacing Worn or Damaged Components

Once the faulty components are identified, replacement parts must match the original specifications. Seals, bearings, and impellers are among the most commonly replaced components during submersible pump repair. Using incompatible materials or incorrect dimensions can shorten service life and increase the risk of failure.

Reassembly and Testing

After reassembly, the pump should be tested under controlled conditions. Insulation resistance, current draw, and vibration levels provide early indications of whether the repair was successful. Testing before reinstallation helps reduce the risk of repeated removal and additional downtime.

How to Fix Submersible Pump Performance Problems

Not all submersible pump issues require full disassembly. Some performance problems can be addressed through targeted corrective actions. Knowing how to fix submersible pump issues efficiently can save time and reduce maintenance costs.

- Cleaning clogged impellers or suction screens to restore flow rate

- Adjusting or replacing worn wear rings to improve hydraulic efficiency

- Repairing or replacing damaged power cables to stabilize electrical input

- Improving installation depth to ensure proper motor cooling

Addressing these issues early can prevent more serious damage that would otherwise require extensive submersible pump repair.

How Long Can a Submersible Pump Run Continuously?

One of the most common operational questions is how long can a submersible pump run continuously. The answer depends on pump design, cooling conditions, application type, and maintenance quality. Many industrial and well submersible pumps are designed for continuous duty, provided they operate within their rated parameters.

Continuous operation is generally acceptable when the pump remains fully submerged, allowing the surrounding fluid to dissipate heat from the motor. Problems arise when water levels drop, flow becomes restricted, or solids accumulate around the motor housing.

| Operating Condition | Continuous Run Suitability | Potential Risk |

| Fully submerged with stable flow | Suitable for continuous operation | Low |

| Partial submersion | Limited continuous operation | Motor overheating |

| High solids or debris | Reduced run time recommended | Seal and impeller wear |

Preventive Measures to Reduce Repair Frequency

Reducing the need for frequent submersible pump repair requires a proactive maintenance approach. Monitoring operating parameters and addressing small issues early can significantly extend pump service life.

- Regular inspection of power cables and seals

- Avoiding dry running through level control systems

- Maintaining clean intake areas to prevent blockage

- Recording operating hours to plan timely maintenance

Conclusion

Submersible pump repair, understanding how to fix submersible pump issues, and knowing how long a submersible pump can run continuously are closely connected topics. Proper diagnosis, correct repair methods, and realistic operating practices work together to ensure reliable pump performance. By applying structured repair procedures and respecting continuous operation limits, operators can reduce failures, control maintenance costs, and achieve stable long-term operation.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号