Sanlian Pump Industry Group is a manufacturing enterprise based on water supply and drainage equipment. The group company integrates R&D, design, casting, production and sales, and provides customers with modern, digital and intelligent comprehensive solutions for fluid transportation and integrated systems.

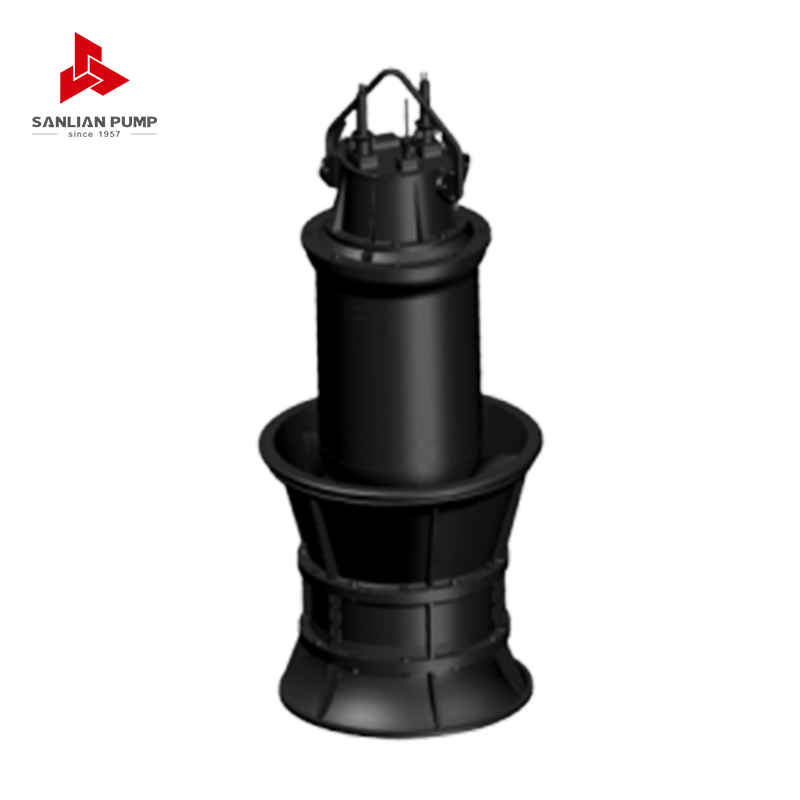

Mixed Flow Pumps Used in HVAC Systems and Wastewater Treatment

Overview of Mixed Flow Pumps

Mixed flow pumps combine characteristics of both axial and centrifugal pumps, allowing fluid to move in a direction that is partially radial and partially axial. This design provides a balance between high flow rates and moderate head, making them suitable for applications where energy efficiency and consistent performance are critical. Mixed flow pumps are widely used in HVAC systems for circulating water and in wastewater treatment plants for moving effluent and sludge.

Advantages of Using Mixed Flow Pumps in HVAC Systems

In HVAC systems, efficient water circulation is crucial for temperature control and energy management. Mixed flow pumps offer several advantages over purely centrifugal or axial designs:

- High flow capacity with moderate head, suitable for large heating or cooling loops.

- Energy-efficient operation, reducing operational costs in commercial and industrial buildings.

- Compact design, allowing easy installation in tight mechanical rooms.

- Reduced cavitation risk due to smooth hydraulic characteristics, enhancing reliability.

Role in Wastewater Treatment Plants

Wastewater treatment involves moving large volumes of water with varying levels of solids. Mixed flow pumps are particularly effective in this environment due to their ability to handle moderate heads and high flow rates without clogging or excessive wear. Key applications include:

- Influent and effluent pumping stations for moving water between treatment stages.

- Sludge recirculation and aeration systems, where continuous, energy-efficient flow is essential.

- Flood control systems, managing variable water levels in urban wastewater networks.

Design Considerations for Mixed Flow Pumps

When selecting a mixed flow pump for HVAC or wastewater applications, several design factors must be considered:

- Flow Rate and Head Requirements: Determine the system’s peak and average flow needs to choose a pump that operates efficiently within its best efficiency range.

- Material Compatibility: For wastewater applications, pumps often require corrosion- and abrasion-resistant materials to handle solids and chemicals.

- Maintenance Accessibility: Ensure the pump allows for easy inspection, impeller cleaning, and bearing lubrication to minimize downtime.

- Motor Type and Drive: Variable frequency drives (VFDs) can enhance energy efficiency by adjusting pump speed based on system demand.

Performance Characteristics

The performance of mixed flow pumps is defined by a balance between flow rate, head, and efficiency. The following table summarizes typical ranges and applications:

| Parameter | Typical Range | Application |

|---|---|---|

| Flow Rate | 50 – 5000 m³/h | HVAC loops, wastewater transfer |

| Head | 5 – 50 m | Moderate pressure applications |

| Efficiency | 65 – 85% | Optimized for energy savings |

| Solids Handling | Up to 50 mm | Wastewater and sludge pumping |

Installation and Maintenance Tips

Proper installation and maintenance are essential for maximizing the lifespan and efficiency of mixed flow pumps. Consider the following:

- Install the pump on a stable, level foundation to minimize vibration and noise.

- Ensure proper alignment between the pump and motor to prevent premature bearing or seal wear.

- Regularly inspect impellers and casings for wear, corrosion, or blockages.

- Monitor operating conditions such as flow, head, and vibration to detect anomalies early.

- Follow manufacturer guidelines for lubrication, seal replacement, and impeller adjustments.

Conclusion

Mixed flow pumps provide a versatile and energy-efficient solution for HVAC systems and wastewater treatment applications. Their ability to handle high flow rates at moderate head levels, combined with adaptability to various fluids, makes them a practical choice for engineers and facility managers. Proper selection, installation, and maintenance ensure long-term reliable operation, helping systems achieve optimal performance while minimizing energy costs and downtime.

English

English 中文简体

中文简体 Français

Français Español

Español Português

Português عربى

عربى

皖公网安备34052302341647号

皖公网安备34052302341647号